Motion Industries

Blockchain Concept for Hazmat Shipment Information Retrieval

In our Information Systems class taught by Professor Benoit Montreuil, creator of the idea of Physical Internet and head of the PI Center at Georgia Tech, we had to realize an innovation project. We found the opportunity of working directly with a client in industry that could benefit from our work directly in a very practical way. Motion Industries is a subsidiary of Genuine Parts Company, leading distributor of industrial parts and products in the US. Our client is a $4.96B company with 300,000 customers, 6M parts inventory and 600+ sales locations in the US. The Hazmat portion of the business has about 100,000 SKUs, for $75M annual revenue, and $20M on hand inventory.

Opportunity

Hazmat Classification: a Cumbersome World

The shipping of HAZMAT products is subject to strict regulations (IATA, DOT) in order to avoid accidents. Before shipping, the HAZMAT classes of the products have to be identified very precisely. The Hazmat class depends on the type of transportation, the quantity and the kind of products. Only a certified employee can allow a shipment. A standardized unique 4-digit code called “UN Code” has been created in order to identify the hazmat class of a product quickly. When MI has the “UN Code” associated to a product, a DGIS (Dangerous Goods Information System) Software, called Label Master, is able to generate all the details for the shipment automatically. MI’s DGISsoftware performs well but it is not integrated into the ERP System. Therefore, even when MI has the UN Code associated to a product, a manual filling of a form has to be done by the certified employees.

However, the “UN Code’’ is not often communicated by MI’s suppliers. In a such case, certified employees have to follow a long procedure in order to find the HAZMAT class of the product. It can take between 30 and 45 minutes per order. Thus, MI wanted to improve its process of hazmat shipments.

Challenges

At a high level, the Hazmat classification process was highly inefficient and time consuming because of the following reasons:

1. Fragmented Data Storage for Hazmat

2. Labor Intensive, manual data entry workflows

3. Limited data sharing with partners

4. Lack of a standardized format, depending on the source of information

5. Missing Hazmat information on receipts of goods from suppliers, created non-compliance issues and possible fines.

Out of those, two elements created major inefficiencies and drove us towards a clear solution.

Operational Drag

One of the main problems we had identified for MI process of clearly defining whether a certain shipment should be categorized as Hazmat or not, is the fact that they have to check characteristics of products on Hazmat each time they are handling the products or preparing them for shipment. They do not receive this information in a standardized manner from their suppliers and it is sometimes very difficult to search for this information given the variety of ways in which a certain item can be shipped (number of items of a SKU, type of shipment, other items it is being packed with, destination, transportation type, state regulations...). Also, from the non-standardized format on information/characteristic of a product, there is also a problem about inconsistency of products’ description and information Blockchain is a solution.

Fragmented Information Sharing: a Disconnected Supply Chain

Today, the problem is that information and specifications about items being produced are held in a centralized database of the manufacturer - then a centralized database for MI, then a centralized database for the 3PL - all disconnected. Hence, the only information that is passed to MI about those products when it is shipped to MI is contained in the shipment documentation. Hence, when the bulk is broken and items are stored in inventory, there is no set of specifications for each particular SKU that follows them on the shelf - the specifications (on Hazmat for instance) was only attached to the shipment as a whole, not the individual products in it. The only information MI has is that it recorded an extra X amount of product A in their inventory. So when those items have to be shipped out, MI has to look for whether the items are Hazmat or not, and upon what conditions they can be considered so, in a manual way. It creates duplication of tasks, because in the past the manufacturer already had to perform this task in a way, and all the work that the manufacturer had done in the past was lost as MI received the shipment and broke bulk.

Solution

Conceptual Definition

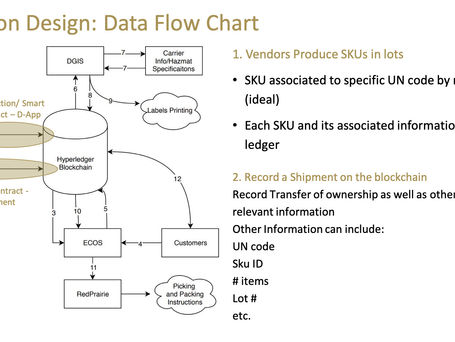

The solution we identified is to store a product ID on a blockchain or distributed ledger. This is a challenging solution because it requires suppliers/manufacturers to be motivated and to understand the opportunity and the impact that this solution can have.

It would be ideal to have a product ID being recorded on a public blockchain whenever a product is manufactured or assembled. This product ID would have for instance: product specifications, type of material, serial number, barcode, lot number, manufacturing location, hazardous material information and more. Once the product is out and available to move around the supply chain, its ID is recorded on the blockchain and is available to be consulted by any node in the network. The proposed solution, in addition to this product ID being on the blockchain, would have another blockchain layer that would function as a smart contract. That is, when the manufacturer prepares a shipment for MI, as all the products in the shipment have a product ID with characteristics listed, a smart contract triggers a similar product ID for the entire shipment - namely, it will consolidate all the information from every product ID of every material in the shipment, and create a product ID for the shipment as a whole. What the smart contract would accomplish is the same process that the employees are doing manually today at the MI warehouse prior to a shipment: namely, verifying each condition for a shipment that will allow them to categorize the shipment as a certain class of Hazmat, or not. This functionality would be automated and trustworthy.

Our Application Platform: Hyperledger Fabric

We identified Hyperledger Fabric as an ideal platform to host this innovative product for Motion Industries. Hyperledger Fabric is an open source, enterprise-grade and permissioned blockchain platform, designed for use in enterprise contexts. One of the great advantages of Fabric that make it so attractive and accessible, is that smart contracts functionalities can be implemented using general- purpose programming languages. The platforms varied characteristics responded well to the system requirements of the solution we conceptualized for the client:

Requirement: Platform to Store and Share Data about HAZMAT Product

HF Functionality: At a high level, HF is a blockchain - it is a tamper-proof, immutable, chronological record of all state transitions of the platform - the “fabric”.Requirement: Identity Management for Network Nodes

HF Functionality: Hyperledger Fabric includes a Membership Identity Service (MIS) in order to propose different levels of permissions according to the user ID.Requirement: Privacy and Confidentiality

HF Functionality: it enables several groups or competitors to use a same network while guaranteeing the privacy and confidentiality of the transactions of each group. Constructs like private data collection allow this for instance.Requirement: Carrier Based Handling Requirements

HF Functionality: Chaincode (Smart Contracts) Chaincode applications encode logic that is invoked by specific types of transactions on the channel.

HF Functionality:

Pluggable Consensus Protocol

HF proposes the possibility of using “Consensus Protocol” as a modular, independent and pluggable component.Thus, consensus can be integrated to any deployment like for example a chaincode.