Chargeback System Re-Design

Capstone Design Academic Project for Newell Brands

Newell Brands is an industry leader in consumer goods with a strong portfolio of well-known brands such as Rubbermaid, Sharpie, Elmer’s, Yankee Candle, and Graco. As Newell Brands has expanded its portfolio of brands since its merger with Jarden Corporation in 2016, it has become increasingly more difficult to establish consistent practices within each division, as is the case for the supplier chargeback process. When defective products are received from a supplier, a supplier chargeback process ensures the supplier is held monetarily responsible for correcting the non-conforming product. Unfortunately, NWL did not have a company-wide standardized chargeback process in place that was capable of achieving the monetary goal of recouping funds. An overwhelming majority of divisions did not have a well-established chargeback process, and in others, it did not exist at all. This leaves millions of dollars on the table in the form of undocumented or unrecouped costs.

What We Did

In a period of 5 months, we went through a current system evaluation, a gap analysis and a systems design procedure to produce a new, comprehensive and standardized chargeback process that could be used and implemented by Newell in a variety of divisions.

Approach & Current Process Findings

The current project primarily utilizes the systems aspect of the Industrial and Systems Engineering (ISyE), emphasizing skills within the system domain of properties and requirements. The Vee Model for Systems Engineering Process (Figure 1) provided a structured approach to the redesign of NWL’s chargeback process. Figure 1 is sectioned by two phases: the documentation phase and the approval phase. As part of the documentation phase, the current system was analyzed, a concept of operations with clear definitions was created, and system requirements and constraints were established along with inflows and outflows. Depicting NWL’s system as a black-box represents the distinct nature and state of each division’s chargeback process. We identified the NCMR as the process trigger and a successful creation of a finalized credit memo as the outflow of the system. The four steps circled in red in Figure 2 provide a comprehensive understanding of the objectives, constraints, and requirements that are necessary to create the proposed solution.

Current State, Gap Analysis

Internal Benchmarking Results

After numerous weeks spent analyzing the current state of things, we closed the internal benchmarking with a gap analysis that allowed us to organize the necessary components of a successful chargeback process. In the tables below, NCMR stands for Non Conforming Materials Report, which is the document triggered whenever a non conformance is identified.

Our Solution, Deliverables and Value

High Level Overview of our Deliverables and the Value Potential

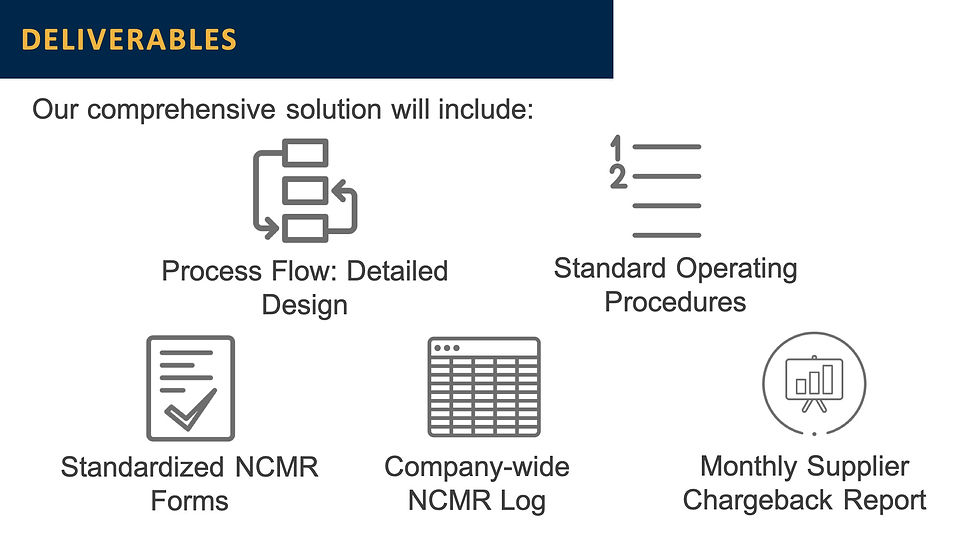

The study of internal process, the gap analysis, the identification of key elements for success, and the external benchmarking allowed us to construct a number of deliverables forming the backbone of the new chargeback process. Our set of documents and systems allowed for a chargeback process that could be easily applied to all the divisions of the company, while allowing for a considerable flexibility to accomodate the inherent differences between division (e.g. tabletop like Calphalon, wiriting like Sharpie). Our deliverables include: a low level process flow chart, indicating every step of the framework, their dependencies, and the roles and responsibilities associated with each step. To specify responsibilities and actions, we developed a detailed SOPfor every role involved in the process, for any necessary step. To ensure compliance and standardization, we built a brand new NCMR form, to produce an accurate and comprehensive record of the defect at hand. It allows consistency with flexible clauses to adapt to all divisions' different environments. Having a standard form also facilitates proper record keeping and improves diligence, making it harder ot leave fields blank and easy to identify what information is missing. Hence, it was all natural for us to also put in place a standardized Company-Wide NCMR Log. Finally, we created a Supplier Scorecard coupled with a monthly supplier chargeback report system. Those would tell NWL in time which suppliers are providing the highest quality of goods, and are th most reliable partners, and which are falling behind.